3D printing shows potential to create wearable electronics

Researchers at the Missouri University of Science and Technology (S&T) have started the project of creating stretchable electronics that can be elongated, compressed, or twisted to fit practically any surface.

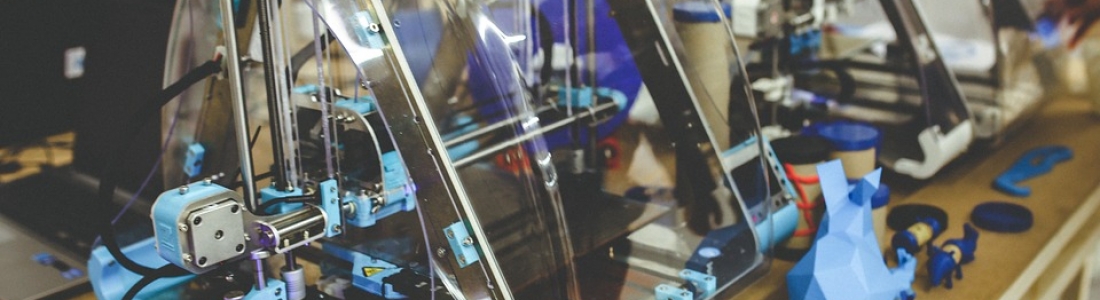

Integrating the wide variety of materials needed to make such an electronic device with such components is proving to be challenging and researchers at Missouri S&T have decided to tackle this challenge using 3D printing, also known as additive manufacturing. Additive manufacturing has the benefit that it can easily change from one material to the another and integrate all the different materials together in one print.This process allows manufacturers to print highly conductive materials onto an elastomer surface layer by layer to create a stretchable electronic device.

At Missouri S&T, researchers are experimenting with a 3D printing approach called ‘direct aerosol printing’. The process involves spraying a conductive material and integrating with a stretchable substrate to develop sensors that can be placed on skin. A working prototype has been created of a stretchable electronic device that can adhere to the face. This project is still in the early phases, however it is believed the technology has a lot of potential, particularly in the biomedical engineering space, because of the soft and conformable nature of the device.

One of the most significant benefits of these electronics is that they can be completely wearable, and can form to any kind of motion, for example, being mounted on the face and detect any small motion from your face. Stretchable electronics could also be developed and installed in shoes and used to measure pressure and weights, the possible applications are extensive.

However, several challenges must be addressed before stretchable electronics become widely used as components in consumer electronics, medical devices and other fields. All the materials needed to make each stretchable electronic device needs to be printable, which means developing ink and printable materials that have all the necessary properties for each type of electronic device. In addition, there are also integration challenges, such as varying temperature requirements among different materials. It is also important to ensure that the stretchable electronics and the malleable surfaces they’re built upon perform and age well together.

One of the biggest research focuses right now is to develop an effective, long-lasting stretchable battery, as the energy device is a very critical component in order for stretchable electronics to be realistic.

Following the perfection of the technology, the products will also need to be scaled-up. 3D printing does make that process more streamlined as it can be easily moved to any location, however there are still a lot of unknown factors. The device itself will also need to be low-cost to create, and eventually biodegradable. Despite these hurdles, researchers are optimistic that stretchable electronics, made using 3D printing, will become more commonplace going forward.

If your company is using 3D printing, you may be eligible for the federal R&D Tax Credit. Contact a Swanson Reed specialist to see if you qualify.