Researchers at Binghamton, SUNY and MIT Identify Issue with 3D Printing

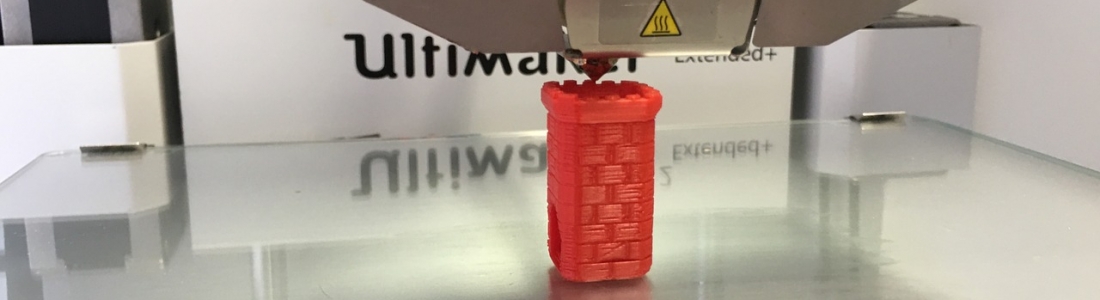

Researchers at Binghamton University, the State University of New York and the Massachusetts Institute of Technology have identified an issue in 3D printers that is slowing down the printing process. If improved, it would allow faster production of 3D models.

In a paper titled, “Rate Limits of Additive Manufacturing by Fused Filament Fabrication and Guidelines for High-Throughput System Design,” researchers discovered that when printing at 0.2mm thickness, 3D printers built at a speed of around 10 to 20 cubic centimeters per hour.

Their findings stated that the printing speed is strongly related to temperature. The pinch-roller mechanism that feeds through the building material has a limited force and feed rate for melting the material completely. If the polymer was pre-heated or printed from multiple openings, the melting rate would increase and the polymer could more easily be pushed through the nozzle with the same amount of pressure. The researchers hope that their findings will inspire work like this in the future.

3D Printing for R&D

New York is the number one hub in the world for 3D printing, ahead of London and Paris, providing 453 3D printers for use.

3D printing is being used increasingly for designing, researching, testing and developing products. The creation of new or improved products with a 3D printer is generally considered an eligible R&D activity.

Businesses claiming the New York Excelsior R&D Tax Credit can receive a refundable tax credit equal to 10% of the federal R&D credit. For a free assessment, contact Swanson Reed R&D Tax Specialists to find out whether your business qualifies.