Automotive batteries for hybrid-electric vehicles are high-capacity electrochemical energy storage systems that provide traction power and facilitate regenerative braking in tandem with a combustion engine. These specialized battery packs enable improved fuel economy and reduced emissions by optimizing the interface between electrical propulsion and traditional internal combustion drives.

The Electrochemical Architecture of Hybrid-Electric Propulsion Systems

The fundamental role of a battery in a hybrid-electric vehicle (HEV) is the storage and rapid discharge of electricity to assist or replace the mechanical output of an internal combustion engine (ICE). Unlike standard lead-acid batteries used in conventional vehicles for starting, lighting, and ignition (SLI), HEV traction batteries are designed for high power density and deep cycling resilience. These systems must withstand thousands of charge and discharge cycles as the vehicle transitions between mechanical propulsion, electric-only operation, and regenerative braking phases.

Diverse Chemistries and Energy Density Dynamics

The evolution of hybrid batteries has seen a transition from robust but heavy Nickel-Metal Hydride (NiMH) systems to high-energy-density Lithium-Ion (Li-ion) paradigms. NiMH batteries, which utilize a nickel-based cathode and a metal-hydride anode, were the cornerstone of early hybrid success due to their inherent safety and tolerance for electrical abuse. However, the push for lighter vehicles and longer electric-only ranges has led the industry toward Li-ion solutions. Lithium-ion batteries offer significantly higher energy density, typically measured in watt-hours per kilogram (Wh/kg), allowing manufacturers to package more energy in a smaller footprint.

| Battery Chemistry | Typical Energy Density (Wh/kg) | Primary Anode/Cathode Materials | Technical Advantage in HEV Context |

|---|---|---|---|

| Lead-Acid | 30 – 40 | Lead / Lead Dioxide | Low cost, reliable for 12V ancillary loads |

| NiMH | 40 – 60 | Metal Hydride / Nickel | High safety, excellent lifecycle for strong hybrids |

| Li-ion (NMC) | 120 – 180 | Graphite / Nickel Manganese Cobalt | High energy density, lightweight, high voltage |

| Li-ion (LFP) | 90 – 140 | Graphite / Lithium Iron Phosphate | Superior thermal stability, lower cost (no cobalt) |

| Li-Polymer | 130 – 200 | Carbon / Metal Oxide Gel | Flexible form factor, high performance |

The energy stored (E) in these packs is a function of the capacity (Q) and the nominal voltage (V), expressed as E = V × Q. In HEVs, the battery must often provide short bursts of high power (P), calculated as P = V × I, where I is the current. This requires low internal resistance and advanced cooling to manage the heat generated by the movement of ions through the electrolyte.

Integration and the Role of Power Electronics

A hybrid battery does not operate in isolation; it is the core of a sophisticated powertrain that includes power inverters and DC-DC converters. Because batteries store and supply direct current (DC) and modern electric motors typically require alternating current (AC) for propulsion, the power inverter is a critical component. During regenerative braking, the motor acts as a generator, creating AC that the inverter must then rectify back to DC to recharge the battery.

Furthermore, the vehicle’s low-voltage systems (lights, infotainment, safety sensors) still require 12V power. In many hybrids, a DC-DC converter replaces the traditional alternator, stepping down the high voltage of the traction battery to the 12V level required by ancillary components. The Battery Management System (BMS) acts as the “brain” of this assembly, monitoring cell voltage, state-of-charge (SOC), and temperature to ensure the longevity and safety of the electrochemical cells.

The Statutory Foundation of the Wisconsin Research Credit

Wisconsin’s commitment to fostering a clean energy economy is reflected in its specialized research and development tax incentives. These credits are primarily codified in Wisconsin Statutes Sections 71.07(4k) for individual income tax and 71.28(4) for corporate franchise and income tax. The state offers a tiered credit system that provides higher benefits for research related to internal combustion engines and energy-efficient products, specifically including automotive batteries for hybrid vehicles.

Definitions of Qualified Research and Vehicles

The Wisconsin legislature has adopted an expansive definition of “internal combustion engine” that explicitly includes substitute products such as fuel cell, electric, and hybrid drives. This ensures that research into the electrical components of a hybrid drivetrain—including the battery, motor, and control systems—receives the same preferential treatment as traditional engine research. The term “vehicle” is similarly broad, encompassing automobiles, trucks, buses, motorcycles, and even construction or garden maintenance equipment.

| Term under Wis. Stat. | Statutory Definition and Inclusion | Relevance to HEV Research |

|---|---|---|

| Internal Combustion Engine | Includes fuel cell, electric, and hybrid drives | Extends enhanced credit to battery and motor R&D |

| Vehicle | Any frame/frame technology with an engine mounted | Includes passenger cars, transit buses, and trucks |

| Qualified Research Expenses | As defined in IRC Section 41, but limited to Wisconsin | Defines what costs (wages, supplies) can be claimed |

The Tiered Rate Structure

Wisconsin’s research credit is structured to incentivize both general innovation and targeted development in specific sectors.

- General Research Credit: Research conducted for any product improvement typically earns a credit equal to 5.75% of the qualified research expenses (QREs) that exceed a base amount.

- Enhanced Research Credit: Research related to internal combustion engines (including hybrid drives) and certain energy-efficient products (including HEV batteries) earns a doubled rate of 11.5% of the QREs exceeding the base amount.

- Startup Provision: For companies with no QREs in the preceding three taxable years, the state allows a flat credit on current-year expenses—2.875% for general research and 5.75% for enhanced research.

This tiered approach recognizes that the development of advanced energy storage and high-efficiency propulsion systems involves significant technical uncertainty and capital risk, justifying a higher level of state support.

Local Department of Revenue Guidance and Administrative Application

The Wisconsin Department of Revenue (DOR) provides administrative interpretation of the law through publications and tax forms. Publication 131, “Tax Incentives for Conducting Qualified Research in Wisconsin,” and the instructions for Schedule R are the primary sources of guidance for taxpayers claiming these credits.

Interpretation of “Energy Efficient Products”

DOR guidance clarifies that the 11.5% enhanced credit applies to research related to the “design and manufacturing of… automotive batteries for use in hybrid-electric vehicles that reduce the demand for natural gas or electricity or improve the efficiency of its use”. This creates a nexus between the electrochemical performance of the battery and the state’s broader energy policy goals. For a battery project to qualify for the 11.5% rate rather than the standard 5.75% rate, the claimant must demonstrate that the research is aimed at one of these efficiency goals.

The application of “efficiency” can be interpreted technically through several lenses:

- Volumetric Efficiency: Research that allows for a smaller battery pack without a loss in power, thereby reducing vehicle weight and increasing overall fuel economy.

- Charging Efficiency: Improvements in the rate at which the battery can accept energy from regenerative braking, which directly reduces the need for the mechanical engine to provide propulsion or generator power.

- Cycle Efficiency: Development of chemistries or management systems that reduce energy loss due to internal resistance or heat generation during rapid discharge.

The Wisconsin Nexus Requirement

A non-negotiable requirement for the Wisconsin R&D tax credit is that the research must be conducted within the state. This is a departure from federal rules, which allow for research conducted anywhere in the United States. If a company operates an R&D lab in Milwaukee and a production facility in Michigan, only the wages paid to the Milwaukee-based researchers and the supplies used in that lab are eligible for the credit.

If research costs are incurred in multiple states and cannot be accurately separated, the DOR allows for a “reasonable allocation” method. However, the burden of proof rests on the taxpayer to demonstrate that the claimed expenses were for activities physically performed in Wisconsin.

Conformity with the Internal Revenue Code (IRC)

Wisconsin generally defines “qualified research” by referencing Section 41 of the IRC. To qualify, a battery research project must pass the “Four-Part Test”:

- Section 174 Test: The research expenses must be of a nature that they could be treated as expenses under IRC Section 174. This requires that the research aim to eliminate uncertainty regarding the capability, method, or design of a product.

- Technological in Nature Test: The process of experimentation must rely on the “hard sciences,” such as engineering, chemistry, or physics.

- Process of Experimentation Test: Substantially all of the activities must involve a process of experimentation, such as modeling, simulation, or systematic trial and error.

- Business Component Test: The research must be intended to develop a new or improved product, process, or software.

Critically, Wisconsin has not conformed to recent federal changes that require the amortization of research expenses. For Wisconsin credit purposes, taxpayers still utilize the pre-2022 federal provisions, allowing for a more straightforward calculation of the credit based on expenses incurred during the taxable year.

The Evolution of Refundability and Liquidity for Startups

One of the most significant shifts in Wisconsin tax policy regarding R&D is the movement toward refundability. For many years, the credit was strictly nonrefundable, meaning it could only be used to offset a taxpayer’s liability. This posed a challenge for innovative startups in the hybrid vehicle sector that were investing heavily in research but had not yet reached profitability.

Increasing Refundable Percentages

Recognizing this market friction, the Wisconsin legislature introduced and subsequently increased a refundable cash option for unused credits:

- 2018 – 2020: Up to 10% of the computed credit could be claimed as a refund.

- 2021 – 2023: The refundable portion increased to 15%.

- 2024 and beyond: For tax years beginning after December 31, 2023, the refundable portion is 25%.

The refundable amount is the lesser of the current year’s computed credit multiplied by the applicable percentage (e.g., 25%) or the total credit remaining after the taxpayer’s current-year tax liability has been reduced to zero. Any portion of the credit that is neither used nor refunded can be carried forward for 15 years to offset future tax liabilities.

| Tax Year Range | Maximum Refundable Percentage | Treatment of Remaining Credit |

|---|---|---|

| Pre-2018 | 0% | 15-year Carryforward |

| 2018 – 2020 | 10% | 15-year Carryforward |

| 2021 – 2023 | 15% | 15-year Carryforward |

| 2024+ | 25% | 15-year Carryforward |

Internal Use Software and Battery Management Systems (BMS)

A frequent area of audit dispute and regulatory guidance involves the software component of hybrid batteries. Modern battery packs are governed by a BMS that requires millions of lines of code to manage voltage balancing, thermal safety, and communication with the vehicle’s engine control unit (ECU).

The Distinction Between IUS and Product-Embedded Software

Federal and state regulations distinguish between “Internal Use Software” (IUS) and software developed as part of a product.

- Internal Use Software: Software used for general administrative functions (e.g., HR, accounting) faces a higher “threshold of innovation” test to qualify for the credit.

- Product-Embedded Software: Firmware or software that is part of a battery management system sold to customers is generally not treated as IUS. This software only needs to meet the standard four-part test.

DOR and IRS guidance clarified that software developed to interact with third parties or to enable a business component (like a hybrid drivetrain) to function is eligible for the credit without meeting the heightened innovation threshold. For an HEV battery manufacturer, this means that the wages of software engineers developing the BMS logic are fully eligible QREs, provided the work is performed in Wisconsin.

Interaction with the Manufacturing and Agriculture Credit (MAC)

Many companies researching hybrid batteries in Wisconsin are also manufacturers. This leads to an intersection with the Wisconsin Manufacturing and Agriculture Credit (MAC), which provides a credit equal to 7.5% of “qualified production activities income” (QPAI) derived from property assessed as manufacturing or agricultural in the state.

Strategic Distinction and Coordination

The MAC and the Research Credit operate differently:

- The Research Credit is an expense-based credit, rewarding the cost of innovation.

- The MAC is an income-based credit, rewarding the success of production.

An important compliance detail from the DOR is that the R&D credit itself must be reported as income for Wisconsin tax purposes. When a claimant computes an R&D credit (e.g., Code 16 on Schedule AD), that amount is added back to the taxpayer’s income. While this creates a small increase in taxable income, the value of the 11.5% enhanced credit far exceeds the tax paid on the addition. Furthermore, companies must be careful to distinguish between research wages (eligible for the R&D credit) and production wages (part of the cost of goods sold for the MAC).

Comprehensive Example: Wisconsin HEV Battery R&D Claim

To illustrate the application of these statutes and guidance, consider a hypothetical Wisconsin corporation, “Madison Power Storage, Inc.” (MPS). MPS is developing a new solid-state battery pack for hybrid-electric transit buses.

Scenario Background

For the 2024 tax year, MPS incurred the following expenses related to their Wisconsin-based R&D center:

- Research Engineers’ Wages: $1,200,000

- Materials and Supplies (Electrolytes, Anode foils): $300,000

- Contract Research (testing at a Wisconsin university): $200,000

- Wisconsin Sales/Income Tax Liability (before credits): $40,000

- Average Wisconsin QREs for 2021-2023: $1,000,000

Step 1: Calculate Total Wisconsin QREs

MPS must first determine their current-year QREs. Following IRC Section 41 and Wisconsin DOR guidance:

- Wages: $1,200,000

- Supplies: $300,000

- Contract Research (65% of $200,000): $130,000

- Total 2024 QREs: $1,630,000

Step 2: Determine the Base Amount

The base amount is 50% of the average QREs for the three preceding taxable years:

- Average QREs: $1,000,000

- Base Amount (50% of $1,000,000): $500,000

Step 3: Compute the Credit at the Enhanced Rate

Because the research relates to automotive batteries for hybrid vehicles that improve the efficiency of electricity use, MPS is eligible for the 11.5% enhanced rate:

- Eligible QREs ($1,630,000 – $500,000): $1,130,000

- Credit Rate: 11.5% (0.115)

- Total Computed Credit: $129,950

Step 4: Apply the Credit and Calculate the Refund

MPS will first use the credit to offset its $40,000 tax liability:

- Offset Liability: $129,950 – $40,000 = $89,950 remaining credit.

- Maximum Refundable Portion (25% of $129,950): $32,487.50.

- Refund Amount: MPS receives the lesser of the remaining credit ($89,950) or the maximum refundable portion ($32,487.50).

- Actual Refund: $32,487.50 cash refund.

- Carryforward: $89,950 – $32,487.50 = $57,462.50 to be carried forward for 15 years.

Technical Uncertainties and the “Process of Experimentation” in Battery Design

For a research project to survive a DOR audit, the taxpayer must demonstrate that they were addressing specific technical uncertainties. In the context of HEV batteries, this often centers on the “balancing act” between energy density, power density, and safety.

Challenges in High-Current Intercalation

During regenerative braking, an HEV battery must accept a very high current in a short period. This rapid intercalation of lithium ions into the anode can lead to “lithium plating” if not managed correctly, which in turn creates dendrites that can cause internal short circuits. Research into anode coatings or electrolyte additives that facilitate faster ion transport without plating constitutes a clear “process of experimentation” that qualifies for the credit.

Managing Thermal Gradients

As batteries discharge and recharge rapidly, they generate heat (Q = I^2 × R × t). If temperature gradients across the battery pack become too high, individual cells will degrade at different rates, leading to premature pack failure. Research into phase-change materials (PCMs) for thermal management or the development of new computational fluid dynamics (CFD) models for liquid cooling systems are considered qualified research activities.

Documentation and Audit Readiness

The DOR maintains a rigorous audit standard for R&D claims, particularly those utilizing the 11.5% enhanced rate. Claimants should be prepared to provide the following documentation:

- Project Lists: A comprehensive list of all research projects, clearly identifying which are claimed under the “energy efficient product” (HEV battery) category.

- Time Tracking: Contemporaneous records of time spent by engineers and technical staff on specific battery research tasks.

- Lab Notes and Reports: Evidence of the “trial and error” process, including failed prototypes and iterations of battery cell designs.

- Expenditure Substantiation: Invoices for research supplies and contracts that clearly show the work was performed in Wisconsin.

The 2026 tax landscape for Wisconsin businesses in the hybrid-electric vehicle sector is one of high potential reward tempered by administrative precision. By understanding the intersection of electrochemical science and state tax statutes, companies can effectively fund the next generation of energy storage technology while contributing to the state’s broader climate and economic goals. The 25% refundability provision, in particular, serves as a vital liquidity tool, ensuring that the most innovative firms can continue their work even in the pre-revenue stages of product development. Through careful compliance with DOR guidance and a focus on verifiable technical advancement, Wisconsin battery innovators can secure their place in the evolving global automotive market.

Who We Are:

Swanson Reed is one of the largest Specialist R&D Tax Credit advisory firm in the United States. With offices nationwide, we are one of the only firms globally to exclusively provide R&D Tax Credit consulting services to our clients. We have been exclusively providing R&D Tax Credit claim preparation and audit compliance solutions for over 30 years. Swanson Reed hosts daily free webinars and provides free IRS CE and CPE credits for CPAs.

What is the R&D Tax Credit?

The Research & Experimentation Tax Credit (or R&D Tax Credit), is a general business tax credit under Internal Revenue Code section 41 for companies that incur research and development (R&D) costs in the United States. The credits are a tax incentive for performing qualified research in the United States, resulting in a credit to a tax return. For the first three years of R&D claims, 6% of the total qualified research expenses (QRE) form the gross credit. In the 4th year of claims and beyond, a base amount is calculated, and an adjusted expense line is multiplied times 14%. Click here to learn more.

R&D Tax Credit Preparation Services

Swanson Reed is one of the only companies in the United States to exclusively focus on R&D tax credit preparation. Swanson Reed provides state and federal R&D tax credit preparation and audit services to all 50 states.

If you have any questions or need further assistance, please call or email our CEO, Damian Smyth on (800) 986-4725.

Feel free to book a quick teleconference with one of our national R&D tax credit specialists at a time that is convenient for you.

R&D Tax Credit Audit Advisory Services

creditARMOR is a sophisticated R&D tax credit insurance and AI-driven risk management platform. It mitigates audit exposure by covering defense expenses, including CPA, tax attorney, and specialist consultant fees—delivering robust, compliant support for R&D credit claims. Click here for more information about R&D tax credit management and implementation.

Our Fees

Swanson Reed offers R&D tax credit preparation and audit services at our hourly rates of between $195 – $395 per hour. We are also able offer fixed fees and success fees in special circumstances. Learn more at https://www.swansonreed.com/about-us/research-tax-credit-consulting/our-fees/

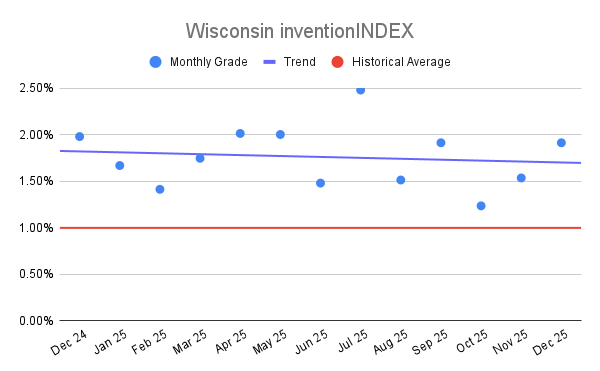

Wisconsin inventionINDEX December 2025

Wisconsin inventionINDEX December 2025  Wisconsin inventionINDEX Novem

Wisconsin inventionINDEX Novem