What is a "Frame" for the Wisconsin R&D Tax Credit?

In the context of the Wisconsin Research and Development tax credit, a frame is a statutorily defined business component that serves as the structural backbone of a vehicle. For specific vehicle types like trucks and motorcycles, the legal definition extends beyond the chassis to include the propulsion, control, and fuel systems. Researching these specific "frame" elements qualifies for an enhanced 11.5% tax credit rate, compared to the standard 5.75%, provided the work meets the four-part test for qualified research: permitted purpose, elimination of uncertainty, technological nature, and process of experimentation.

In the context of the Wisconsin Research and Development tax credit, a frame is the structural and mechanical backbone of a vehicle, specifically defined by statute to include the propulsion, control, and fuel systems for trucks and motorcycles. This legal definition determines eligibility for an enhanced 11.5% tax credit rate when designing internal combustion engines or their modern technological equivalents such as fuel cell or electric drives.

The integration of engineering principles and tax law in Wisconsin creates a unique environment for automotive and engine research. Unlike the federal research credit, which relies on broad definitions of business components, Wisconsin provides specific statutory definitions for what constitutes a "frame" in the pursuit of high-tier tax incentives. This requires a dual-layered understanding: first, of the mechanical role a frame plays in vehicle dynamics, and second, of how the Wisconsin Department of Revenue (DOR) interprets these structures through the lens of the Wisconsin Statutes. The frame is not merely a piece of hardware; it is the boundary of the "business component" for which a taxpayer can claim accelerated tax benefits. Understanding this distinction is essential for engineering firms, manufacturers, and research institutions operating within the state.

The Engineering Foundation of Vehicle Frames in Research and Development

The vehicle frame, historically referred to as the chassis, serves as the primary supporting structure of a motor vehicle. It is the architectural foundation to which all other mechanical, electronic, and structural components are attached, effectively functioning as the skeleton of the mechanical organism. In the realm of research and development, the frame's role extends beyond mere support; it is the critical interface that must manage the complex interplay between static weight, dynamic loads, and vibrational energy generated by the powertrain.

Engineers conducting research on vehicle prototypes must account for the frame's ability to deal with a variety of forces without undue deflection or distortion. These forces include the weight of the body, passengers, and cargo, as well as the torsional twisting transmitted by uneven surfaces and the lateral forces generated by road conditions or steering. Furthermore, the frame must be engineered to withstand the torque generated by the engine and transmission, as well as the longitudinal tensile forces encountered during acceleration and the compression forces experienced during braking. In modern vehicle research, the frame also plays a critical role in occupant safety, as it is responsible for resisting and softening the impact of crashes through energy dissipation zones.

Comparative Analysis of Vehicle Frame Architectures| Frame Type | Construction Methodology | Primary Application in Research | Structural Advantage |

|---|---|---|---|

| Ladder Frame | Two longitudinal rails connected by transverse cross-members. | Heavy trucks, pickups, and buses. | High load-bearing capacity and durability. |

| Unibody | The vehicle body serves as the structural frame. | Modern passenger cars and SUVs. | Light weight and high torsional rigidity. |

| Space Frame | Interlocking network of tubes or extrusions. | Racing vehicles and high-performance sports cars. | Exceptional strength-to-weight ratio. |

| Modular Chassis | Segmented sections that can be interchanged or adjusted. | Electric vehicle platforms and commercial trucks. | Flexibility in wheelbase and payload configuration. |

Research in chassis engineering focuses on the optimization of these structures using computer-aided design (CAD) and finite element analysis (FEA). These technologies allow researchers to simulate the performance of a prototype frame under real-world conditions before a physical model is even fabricated. The goal is often to identify the "critical point" of highest stress, where failure is most likely to occur, and to refine the material thickness or geometry to enhance bending stiffness and handling characteristics.

The Statutory Context of the Wisconsin Research and Development Tax Credit

The Wisconsin Research and Development tax credit is an incentive designed to spur innovation within the state's borders. For researchers in the automotive, power, and manufacturing sectors, the definition of "frame" is not a matter of engineering opinion but of statutory decree. Under Wis. Stat. § 71.07(4k) and § 71.28(4), the state defines "frame" with extreme specificity, separating it from the vehicle's "body" and "tires" and aligning it with the propulsion and control systems of the vehicle.

Statutory Definition of "Frame" by Vehicle CategoryThe Wisconsin legislature has provided distinct definitions for the term "frame" depending on the specific application of the engine and vehicle under research. These definitions are paramount because they determine which components of a research project fall under the "Enhanced Research Credit" tier of 11.5%, rather than the general tier of 5.75%.

| Statutory Vehicle Type | Definition of "Frame" | Key Exclusions |

|---|---|---|

| Motorcycle | Includes every part of the motorcycle. | Tires. |

| Truck | Includes the control system, the fuel train, and the drive train. | Tires and any comfort features located in the cab. |

| Generator | Includes control modules, fuel train, fuel mixers, generator unit, heat exchangers, and exhaust train. | General structural housing not related to the power unit. |

These statutory definitions are found in identical language across the individual income tax sections (Chapter 71.07), corporate franchise tax sections (Chapter 71.28), and insurance company sections (Chapter 71.47). The inclusion of the "control system" and "drive train" within the definition of a truck frame is a significant legal nuance. It indicates that for tax purposes, the state views the frame as a holistic mechanical system rather than just a steel chassis. This allows researchers working on engine management software or drivetrain optimization to potentially qualify for the enhanced credit rate if their work is integrated into the vehicle's propulsion architecture.

Application of the Law: The Tiered Research Credit Structure

Wisconsin's research credit structure is tiered based on the nature of the research activities being performed. The state seeks to provide a "super" credit to specific industries that are foundational to the Wisconsin economy, particularly internal combustion engine manufacturing and energy-efficient technology development.

The 11.5% Enhanced Credit for Engine and Frame ResearchResearch related to the design of internal combustion engines and their associated frames qualifies for the 11.5% rate. Crucially, the law defines "Internal Combustion Engine" to include modern alternatives. Under Wis. Stat. § 71.07(4k)(a)2, this includes substitute products such as fuel cell, electric, and hybrid drives. This ensures that as Wisconsin companies pivot toward electrification and hydrogen power, their research remains eligible for the highest available incentives.

The "Vehicle" associated with this research is defined as any vehicle or frame in which or on which an engine is mounted for use in mobile or stationary applications. This encompasses a vast array of equipment beyond just automobiles, including snowmobiles, personal watercraft, construction equipment, lawn and garden maintenance equipment, and aircraft.

Calculation Methodology for the CreditThe Wisconsin research credit is calculated based on the increase in qualified research expenses (QREs) over a base amount. The "base amount" is defined as 50% of the average QREs from the three immediately preceding taxable years.

The mathematical representation of the credit for engine and frame research is:

Tax Credit = 0.115 × (QRE_Current - (0.5 × QRE_Avg_Prior_3))

For businesses that had no qualified research expenses in the prior three years—often the case for startups or companies launching new R&D divisions—the credit is simplified to 5.75% of the current year's qualified research expenses.

Qualified Research Expenses (QREs) and IRC Section 41Wisconsin defines QREs by referencing Section 41 of the Internal Revenue Code (IRC). This means that while the rate and the frame definitions are specific to Wisconsin, the types of costs that can be included follow federal standards. Eligible expenses generally fall into three categories:

- Wages: Payments made to employees for "qualified services," which include engaging in research, supervising research, or directly supporting research. For frame research, this includes the time of mechanical engineers, CAD designers, and prototype fabricators.

- Supplies: The cost of tangible property used in the conduct of research. This includes materials for prototype frames, test components, and specialized equipment that is not subject to depreciation.

- Contract Research: 65% of the amount paid to third parties to conduct research on the taxpayer's behalf. In some cases, such as payments to universities or specific research consortia, this can be increased to 75% or 100%.

Wisconsin Department of Revenue (DOR) Guidance and Compliance

The Wisconsin Department of Revenue provides administrative guidance through various publications, most notably Publication 131, Tax Incentives for Conducting Qualified Research in Wisconsin. This guidance emphasizes that for expenses to be eligible, the research must be conducted entirely within the state of Wisconsin.

The Four-Part Test for Frame ResearchTo satisfy the DOR that activities related to a frame or engine constitute "qualified research," the taxpayer must meet the federal four-part test as adopted by Wisconsin:

- Permitted Purpose: The research must aim to create a new or improved business component in terms of function, performance, reliability, or quality. For a truck frame, this could be increasing the load-bearing capacity while reducing the weight by 15%.

- Elimination of Uncertainty: The researcher must intend to discover information that would eliminate uncertainty regarding the capability, method, or design of the business component. If an engineer already knows exactly how a frame will perform, it is not research; it is routine engineering.

- Technological in Nature: The research must fundamentally rely on principles of engineering, physics, or materials science. Developing a frame using new high-strength steel alloys is technological; choosing a frame color for aesthetic reasons is not.

- Process of Experimentation: The activities must involve a systematic process of evaluating alternatives through modeling, simulation, or trial-and-error testing. The use of FEA to refine the cross-member placement on a ladder frame is a prime example of a process of experimentation.

Taxpayers must be cautious regarding what the DOR excludes from frame research. For trucks, "comfort features located in the cab" are explicitly barred from the definition of a frame. This means that if an engineering team is simultaneously redesigning a truck chassis and the ergonomic layout of the driver’s seat, the hours and materials dedicated to the seat are not eligible for the 11.5% credit rate. Furthermore, research conducted after the beginning of commercial production or research related to the adaptation of an existing product for a specific customer’s need is generally excluded.

Detailed Case Study: Research on a Zero-Emission Heavy-Duty Truck Frame

To illustrate the interplay of engineering research and Wisconsin tax law, we consider the hypothetical case of "Great Lakes Propulsion & Chassis," a firm located in Waukesha, Wisconsin.

Phase 1: Identifying the Business ComponentThe firm is developing a new frame for a hydrogen-powered tractor-trailer. Because the hydrogen fuel cell serves as a substitute for an internal combustion engine, the project falls under the scope of the enhanced 11.5% research credit. The "business component" being improved is the "truck frame," which, under Wis. Stat. § 71.28(4)(ab)1, includes the structural rails, the control system, and the fuel train.

Phase 2: Addressing Technical UncertaintyThe engineering team faces uncertainty regarding how the high-pressure hydrogen fuel tanks will affect the torsional rigidity of the ladder frame. Conventional frames are not designed to support the concentrated weight of these tanks while maintaining the flexibility required for off-road maneuvering. This represents a "design uncertainty" that satisfies the first part of the four-part test.

Phase 3: The Process of ExperimentationThe team utilizes FEA to model four different cross-member configurations. They fabricate three prototype frame sections using a new aluminum-scandium alloy to test weight reduction vs. durability. They subject these prototypes to "shake-table" testing to simulate 500,000 miles of road vibration. Each iteration and testing protocol is documented in an innovation log.

Phase 4: Calculating the CreditThe project incurs the following QREs in Wisconsin:

- Wages for Engineers: $800,000.

- Prototype Materials (Supplies): $350,000.

- Outside Testing Lab (Contract Research): $100,000 (of which $65,000 is eligible).

Total Current QREs = $1,215,000.

The firm's average QREs for the three preceding years was $600,000.

Base Amount = $600,000 x 0.5 = $300,000.

Excess QREs = $1,215,000 - $300,000 = $915,000.

Applying the 11.5% rate:

Credit = 0.115 × $915,000 = $105,225

Phase 5: Refundability and CarryforwardFor the 2024 tax year, the firm has a Wisconsin tax liability of $50,000. They use $50,000 of the credit to eliminate their tax due.

The remaining credit is $55,225.

The firm is eligible for a refund of up to 25% of their total credit ($105,225 x 0.25 = $26,306.25).

Because the remaining credit ($55,225) is greater than the 25% refund cap, they receive a refund of $26,306.25.

The leftover $28,918.75 is carried forward to the next year.

Historical Evolution and Policy Rationale of the Frame Definition

The specific definitions of "frame" in the Wisconsin Statutes were not accidental; they were the result of targeted legislative efforts to protect the state's industrial base. In 2005, Assembly Bill 243 and Senate Bill 103 were introduced to provide increased credits for designing internal combustion engines for vehicles. The legislation recognized that companies like Harley-Davidson (motorcycles) and Mercury Marine (boats) performed research that was inextricably linked between the engine and the structure that housed it.

By defining the motorcycle frame as "every part... except the tires," the legislature ensured that virtually all R&D performed by a motorcycle manufacturer would qualify for the higher 11.5% rate. Similarly, for trucks, the inclusion of the "drive train" in the frame definition acknowledged that in heavy commercial vehicles, the engine and the chassis are a singular integrated system. The exclusion of "comfort features" was a compromise to ensure the credit focused on the "hard" engineering that drives industrial competitiveness rather than luxury amenities.

Refundability Milestones in Wisconsin R&D Tax Policy| Tax Period | Refundable Percentage | Legislative Context |

|---|---|---|

| Pre-2018 | 0% (Non-refundable) | Credits could only offset tax liability or be carried forward. |

| 2018 - 2020 | 10% | Introduction of limited refundability to help pre-revenue startups. |

| 2021 - 2023 | 15% | Expanded support during economic shifts. |

| 2024 and Later | 25% | Maximum refundability for all research credit categories. |

The increase to 25% refundability in 2024 represents a significant shift in Wisconsin tax policy, making the state one of the most aggressive in the nation for supporting R&D liquidity. For a firm conducting frame research, this provides a direct cash infusion that can be reinvested into further testing equipment or engineering talent, regardless of current profitability.

Audit Risks and Best Practices for Vehicle Frame Research

The Wisconsin DOR is known for its rigorous auditing of the research credit, particularly when a taxpayer claims the 11.5% enhanced rate. Auditors will scrutinize the "frame" definition to ensure that ineligible components (like truck tires or cab amenities) have been properly excluded.

Documentation Strategy for Frame ProjectsTo survive a DOR audit, researchers should maintain a contemporaneous record that links every hour of wage expense and every dollar of supply cost to a specific technological uncertainty related to the frame or engine.

- Innovation Logs: These should detail the "baseline" performance of a frame and the specific "target" performance the research aims to achieve.

- Engineering Drawings and CAD History: Maintaining versions of drawings shows the "process of experimentation" as the design evolved to overcome technical hurdles.

- Test Failure Documentation: In many ways, documenting a failed test is more valuable for an R&D credit than documenting a success. A failure proves that the outcome was "uncertain" at the outset.

- Time Tracking by Sub-System: For truck research, engineers should track time specifically to the "drive train," "fuel train," or "control system" to substantiate the 11.5% rate and clearly separate it from any time spent on excluded "comfort features".

Future Implications: The Frame in the Age of Autonomy and Electrification

As vehicle technology shifts toward autonomous and electric platforms, the definition of "frame" continues to evolve in practice. For an autonomous truck, the "control system" (which is statutorily part of the frame) now includes complex sensor arrays and high-performance computing units. A researcher might argue that the development of the AI-driven braking controller is a "frame improvement" eligible for the 11.5% credit because it is an integral part of the vehicle's control system.

Similarly, in electric vehicles, the battery pack is often a structural member of the frame (unibody-battery integration). Wisconsin's inclusion of "automotive batteries for hybrid vehicles" and "substitute products" in the engine and frame definitions provides a clear pathway for these innovations to be captured at the enhanced credit rate. The "frame" of the future is as much about digital control and energy storage as it is about steel and aluminum.

The Wisconsin Research and Development tax credit remains a vital tool for the state’s manufacturing and engineering sectors. By providing a clear, albeit complex, definition of "frame" and "vehicle," the statutes allow for targeted investment in the core mechanical technologies that define the modern industrial landscape. For the researcher, the challenge is to ensure that the rigorous engineering of the physical prototype is matched by equally rigorous documentation and statutory interpretation. When these two fields—engineering and tax law—are successfully navigated, the result is a significant competitive advantage that fosters the next generation of transportation and power innovation within the state of Wisconsin.

Who We Are:

Swanson Reed is one of the largest Specialist R&D Tax Credit advisory firm in the United States. With offices nationwide, we are one of the only firms globally to exclusively provide R&D Tax Credit consulting services to our clients. We have been exclusively providing R&D Tax Credit claim preparation and audit compliance solutions for over 30 years. Swanson Reed hosts daily free webinars and provides free IRS CE and CPE credits for CPAs.

What is the R&D Tax Credit?

The Research & Experimentation Tax Credit (or R&D Tax Credit), is a general business tax credit under Internal Revenue Code section 41 for companies that incur research and development (R&D) costs in the United States. The credits are a tax incentive for performing qualified research in the United States, resulting in a credit to a tax return. For the first three years of R&D claims, 6% of the total qualified research expenses (QRE) form the gross credit. In the 4th year of claims and beyond, a base amount is calculated, and an adjusted expense line is multiplied times 14%. Click here to learn more.

R&D Tax Credit Preparation Services

Swanson Reed is one of the only companies in the United States to exclusively focus on R&D tax credit preparation. Swanson Reed provides state and federal R&D tax credit preparation and audit services to all 50 states.

If you have any questions or need further assistance, please call or email our CEO, Damian Smyth on (800) 986-4725.

Feel free to book a quick teleconference with one of our national R&D tax credit specialists at a time that is convenient for you.

R&D Tax Credit Audit Advisory Services

creditARMOR is a sophisticated R&D tax credit insurance and AI-driven risk management platform. It mitigates audit exposure by covering defense expenses, including CPA, tax attorney, and specialist consultant fees—delivering robust, compliant support for R&D credit claims. Click here for more information about R&D tax credit management and implementation.

Our Fees

Swanson Reed offers R&D tax credit preparation and audit services at our hourly rates of between $195 – $395 per hour. We are also able offer fixed fees and success fees in special circumstances. Learn more at https://www.swansonreed.com/about-us/research-tax-credit-consulting/our-fees/

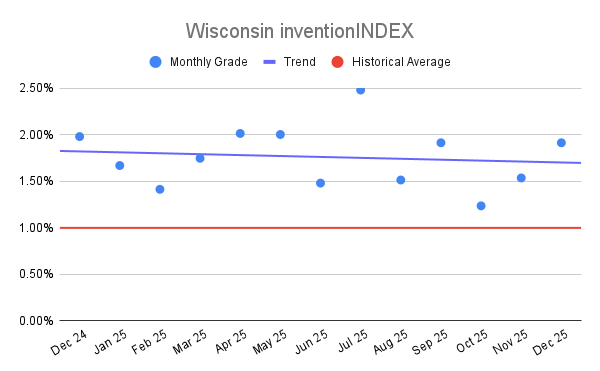

Wisconsin inventionINDEX December 2025

Wisconsin inventionINDEX December 2025  Wisconsin inventionINDEX Novem

Wisconsin inventionINDEX Novem